1969race 125,

This picture of the pedal box will hopefully explain where my legs go.

The throttle bodies and trumpets go into the airbox above my feet. Flexible bellows seal.

The hood is operational and when down does not move at all even at 125mph. It does have a cover though. I am very sheltered when driving with the hood down and the side windows up. I can even drive in quite heavy rain and stay dry.

When the hood is up I do take it steady or use "bungy" cords to secure the hood frame to the roll cage....just in case.

Engine Spec.

Engine.............. ................. Fiat 2 litre 131 twin cam

cylinder head..................... Integrale 16 valve, 3 angle valve seats, sodium filled exhaust valves, spring seats cut further into the head. GC triple springs.

cams................................... 280 degrees duration 10.5 mm lift

head bolts ..........................12.9 grade GC

pistons ...............................131 SOHC Flat top with my design of valve cut out, small bowl, crowns ceramic coated by AEA Technology

CR.......................................10.2:1

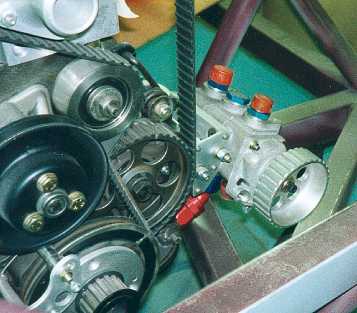

cambelt.............................. 25.4 mm wide GC supplied

crank.................................. Stock with 7/16" UNF grub screws in cross drillings, oil ways modded as per GC book.

block ..................................Bored and honed with deck plate, oil way core plugs replaced with stainless steel items. Oil inlet now into the front of the block.

conrods ..............................Balanced on home made device

rod bolts............................ ARP

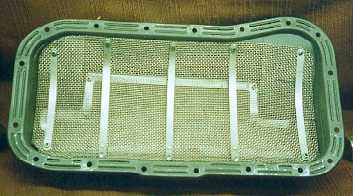

sump.................................. John built dry sump with scraper and gauze

oil pump .............................Titan 3 stage belt driven

flywheel .............................steel to accept Fiat 130 TC ring gear and Ford clutch cover and plate, Saab concentric clutch release bearing.

induction ............................43mm dia. throttle bodies, GC manifold, front mounted K&N air filter.

ignition ..............................distributor less

control ...............................electronically mapped Weber Alpha with homemade loom.

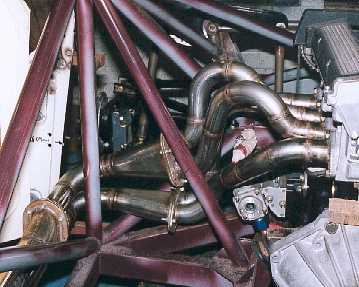

exhaust ..............................tubular, 4-2-1 manifold, 2 1/2" stainless system with expansion chamber and 3" bore silencer, designed to flow 2.2cfm per bhp as per David Vizard.

Water.................................Front mounted thermostat in home made housing, swirl pot and water oil heat exchanger.

John